Ridge Tiles

Roof tiles are durable, resistant to fire and high winds and even recyclable at the end of a long-life. Of course, regardless of whether they are made of clay, slate or concrete no ridge can last forever and this is doubly true for the mortar that keeps older ridges in place.

Eventually, ridge tiles will start to wear down, crack and come loose as their mortar weakens. You may find this happening to your own roof right now; in which case you’ll need to start thinking about removing the old tiles and either re-fitting them or installing a new ridge all together – perhaps even a more modern, dry-fix alternative.

What type of Ridge Tiles are available ?

Whilst all ridge tiles are designed to connect the two planes of your roof and deflect the rain, there are different types to suit different styles of home. Knowing which is best for yours is the first step towards getting appropriate replacements.

Angled Ridges

These have a more geometric design than other types of ridge tiles, ideal for homes more contemporary and minimalist. They are well suited for flat tile and slate roofs and come in capped or legged versions for a traditional looking finish to your ridge line or pitches between 30 – 60 degrees respectively

Half Round Ridges

The most common and popular style of ridge, these semi-circled tiles are perfect for a wide variety of different styles incl. Plain, pantile and interlocking. Thanks to their popularity you’ll find them available in a wide array of different colours to suit almost any design of roof.

Mono Ridge

As the name would suggest, these types of ridge tiles have a flat surface on side, designed for use along mono styles of roof. That being said, they are not all the same with both half-round and angled version available.

What is the biggest benefit your customer will get from this? Keep your target audience in mind.

Two different installation techniques..

- Dry Ridge System

- Wet Ridge

For years, roofers have used the traditional sand and cement mortar method to fix ridge and hip tiles to roofs. Ridge and hip tiles run across the peak of the roof, providing the perfect clean finish to a roof, so it is important that they are installed securely.

Dry Ridge systems have become popular in recent years as an alternative method of fixing ridge and hip tiles to the roof because the more traditional sand and cement method has a number of issues. Using mortar to fix roof ridge tiles is not only time consuming, but the mortar often cracks and falls out over time. This is partly due to temperature fluctuations and weather conditions, leading to an unstable roof ridge that is exposed to the elements. Additionally, mortar-fixed ridge tiles require regular maintenance to prevent them from disconnecting and falling off.

Additionally, the British Standards, particularly BS5534 and BS 8216:2018, suggest that the traditional mortar method of fixing tiles onto roofs should only be used where absolutely necessary, for example in period or heritage properties, and for simple repairs.

What is a Dry Ridge System ?

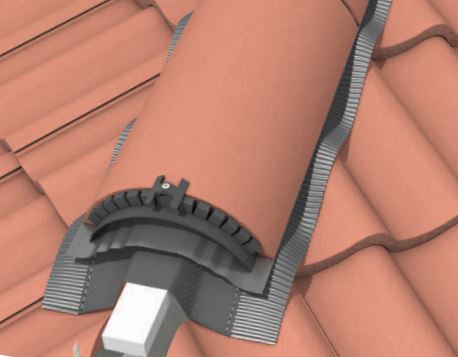

The dry ridge system simply involves fixing ridge and hip tiles to a roof without sand or cement mortar, but instead with screws and clamps, which fix each ridge tile to the roof, with waterproof unions beneath the screws to divert water away from the join.

One of the most popular forms of dry ridge systems is the roll-out dry ridge system. The ridge roll is laid out along the ridge before the ridge tiles are installed, to provide a surface on which to connect the ridge tiles. The roll-out ridge system provides ventilation through the roll of the membrane, whilst also creating a waterproof and weatherproof roof ridge.

How to install a Dry Ridge System?

Depending on the dry ridge system you choose, the installation process may vary slightly. We always recommend following the manufacturer’s installation instructions.

Step one: Lay the roofing underlay as normal, and batten the roof up to the top course of roofing battens.

Step two: Adjust the brackets to get them the appropriate height (this depends on your roof pitch and size of tiles). Fix a batten support bracket to the apex of each rafter with stainless steel ring shanked nails

Step three: Lay a timber batten between the support brackets, and then bend the upstands over the batten and fix in place.

Step four: Lay and fix the roofing tiles in place on each side as per the manufacturer’s recommendations.

Step four: Lay and fix the roofing tiles in place on each side as per the manufacturer’s recommendations.

Step five: When the top course tiles are dry, roll the vent roll along the roof ridge. Tack the roll at intervals using staples or roof felt nails. Then remove the backing of the sealing strip, and push the sealing strips down to follow the contours of the roofing tiles.

Step six: Lay the ridge tiles along the ridge, inserting a ridge union in each gap between the tiles. Then screw the clamping plate over the ridge tile and into the batten.

Step seven: Don’t forget to use an end cap or a block-end ridge at the end of the roof ridge.

What are the benefits to a Dry Ridge System ?

- Installation: The installation process is fairly quick and simple, which can result in big savings in terms of the cost of labour and time it takes to install

- Low Maintenance: Once installed, a dry ridge system requires very little maintenance, unlike the traditional mortar-based ridge system – which requires regular maintenance to replace any degraded mortar

- Weatherproof: You can be confident that during any bad weather and strong winds your ridge tiles will not blow off and cause damage to your roof or anything below. The dry ridge system is also waterproof, preventing any potential water entering into your roof space, which can often occur on any damaged mortar-based ridge tile applications.

- Flexibility: By installing a dry ridge system it provides your roof with a level of flexibility that is not obtainable with mortar-based ridge systems. Roofs will naturally experience some movement, whether it is from vibrations of nearby transport and machinery, or through thermal expansion and contraction. These types of movement can cause cracks to appear within the mortar-based ridge systems, however due to the flexibility of the dry ridge system it allows movement without any risk of damage

- Ventilation: Another great feature of the dry ridge system it can provide a level of ventilation that is otherwise impossible with the more traditional mortar-based tiles. The ‘roll-out’ ridge can allow moisture to move out of the roof void, which helps to prevent any build-up of condensation that could lead to rot and other issues that could then lead to structural damage.